Furniture industry greenwashing

The UK furniture industry in general has a huge negative impact on the environment, with as many as 3 million pieces of office furniture going to landfill every year and contributing to 30% of a building’s carbon emissions over their lifecycle.

And 59% of the 20 million tonnes of waste generated by the UK each year comes from the construction industry, including interior fittings, fixtures and textiles.

This isn’t just about materials and waste. Design and manufacturing are often the crux of the problem, stemming from a tendency to think short-term about a product’s use – without looking at the bigger picture. Individual products are often labelled ‘sustainable’ without revealing the whole story. All aspects of the supply chain, manufacturing process, and life cycle of a piece of furniture count in our embodied carbon impact.

Industry-wide ‘greenwashing’ is partly about failing to look holistically at the problem, about silo thinking, and about ignoring effects further down the chain.

We try to do things differently.

How we do sustainability

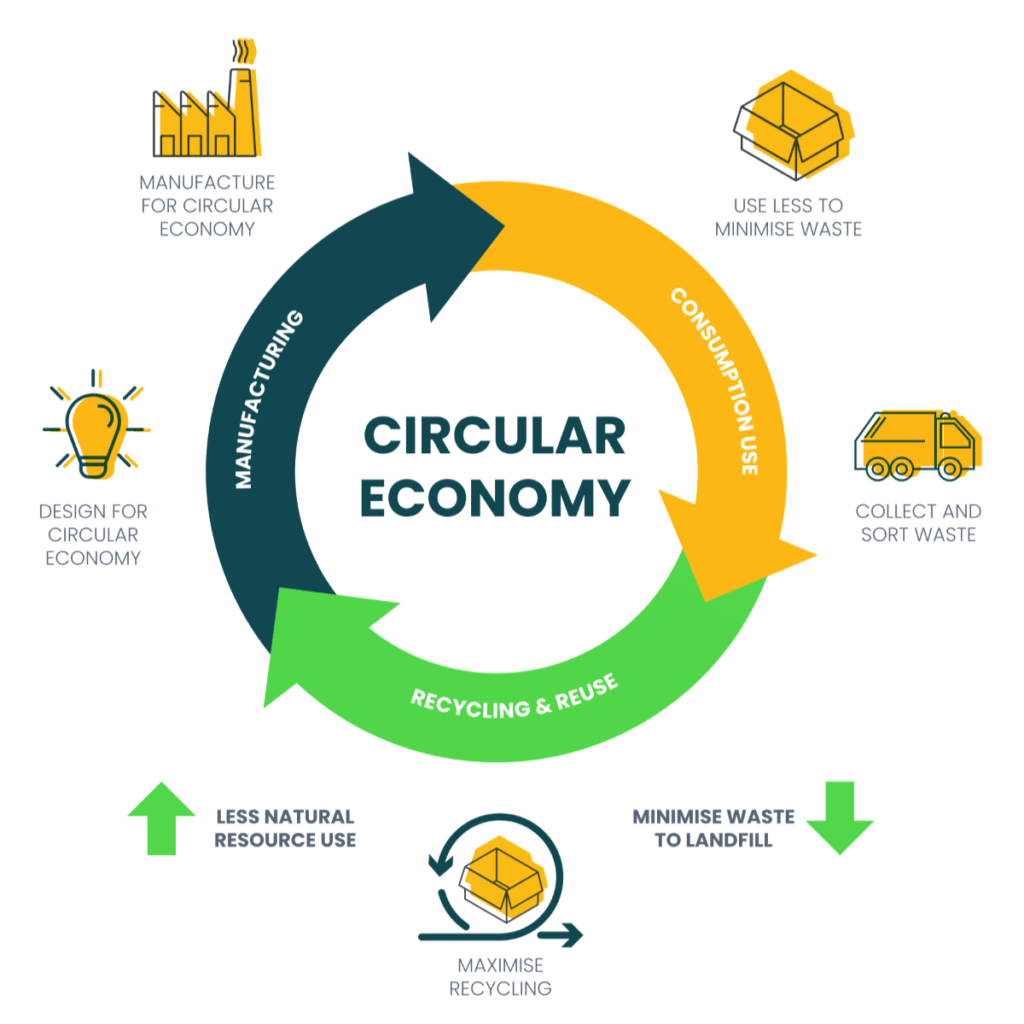

At Friends of Wilson we’re committed to addressing not only our supply chain, but also the complete lifecycle (circular economy) of our products. We ask questions about material origin, longevity, repurposing, recycling, and waste – and we actively engage with our suppliers to understand and improve their impact too.

Sustainability has always been integral to our value system. From the beginning, our founder Lynne Wilson sought to minimise waste in her concepts, and all our design thinking – from initial sketch to finished product – is based on minimal impact and maximum simplicity.

We also ask if sustainability as a concept goes far enough. To sustain means to keep things as they are. We ask if we can do more to progress thinking away from the need for newness while encouraging reuse, recycle and repair.

We use sustainable materials

Wool felt

A completely natural, 100% biodegradable fibre with multiple uses across our product range, and easy to repurpose and recycle.

Bamboo

Sourced from China (its eco-system of origin) where it grows without being invasive, bamboo is renewable, fast-growing, healthy for the soil and water supply, and great for carbon-capture.

Wood

Grown sustainably in FSC-managed forests, natural wood without toxic coatings or adhesives is still one of the most sustainable materials we have.

PET

PET

A part-recycled polyester, PET has a high melting-point, which means it can be recycled and reformed in numerous ways across the product life cycle.

Traditional methods meets innovative design

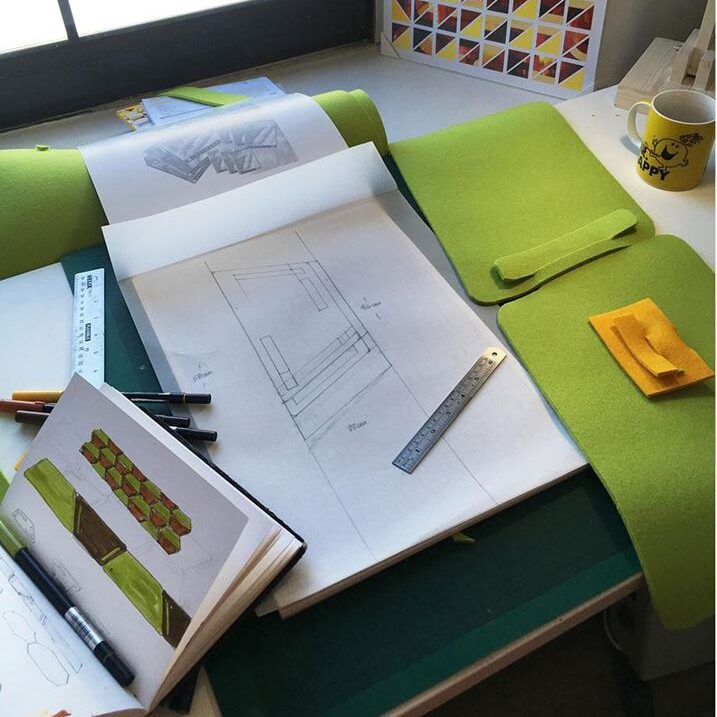

Mother nature is efficient and holistic in her own designs for the planet. So we spend time exploring biomimicry and biophilic design, as well as the sustainable principles and methods of traditional crafts, architecture, and engineering.

In our workshops we test these design principles and see if we can apply them to our own products, and we have a lot of fun along the way!

Because we value the wellbeing impact of biophilic design from a space design, acoustic, tactile, and multi-sensory point of view – we also appreciate how biophilia (love of living things) and sustainability go hand in hand.

Waste-free manufacturing

We take a hands-on approach to our design for manufacture, which means using simple, functional techniques with original, clever details. Nothing unnecessary for the look and integrity of a product makes it into the process. And we minimise waste by making further products from offcuts.

Life cycle of our products

We care what happens to our acoustic room dividers and wall panels after installation as this is as much a part of embodied carbon as the original manufacture and choice of materials.

That’s why we ensure all our modular screens and panels are easily disassembled for moving, cleaning, or repairs, with replaceable parts. We also build agility into our designs so that spaces can be changed or divided up in different ways.

And when they really have come to the end of their lives, we make sure they can be easily dismantled for recycling.

Minimum means for maximum effect

We’re extremely proud of our efforts, and record, on sustainability because we know our low impact approach works throughout our chain of design, manufacture and supply.

But while seeing ourselves as leaders and more than a little unconventional, we’re constantly open to learning and improving, and we love connecting with others on this vital topic. We’re aware that in this climate emergency, there’s so much more to do and not much time to do it.

We see ourselves as contributors to an ongoing conversation about how we can raise environmental standards across our industry and minimise our impact on the natural world. Learn more about Lynne’s talk about sustainable design here.

Lynne Wilson - In conversation

Learn more about Lynne’s talk about sustainability and design for the circular economy here.